焚烧系统

大型化工工业、食品工业、石化工业、制药工业的各种加工,生产过程中产生的废气或废液,需要对废气,废液进行焚烧处理,并对烟气和工艺气体进行净化。

对于这些应用,RVT公司提供包括钢结构、管道和特定EMSR、过程控制和安全技术的交钥匙系统工程。我们的燃烧器系统为每种应用工况定制化设计,以符合法律法规框架下最优的净化处理措施。在废物投料循环过程中,根据介质的不同,必须遵守不同的安全规定。一般来说,不同介质是通过单独的,特殊设计的进气或液体喷枪输送到燃烧室的。只有在燃烧器出口,废弃物与助燃空气混合,并充分燃烧。

废液通过机械雾化或空气、蒸汽或氮气等辅助介质雾化进入燃烧室。根据废物种类和条件参数,提出了技术和经济上的最优解决方案。

当要处理高热值或易燃的废气物时,应按照ATEX指令进行安全评估。必要时,废气管道需配备静态或动态阻火器。

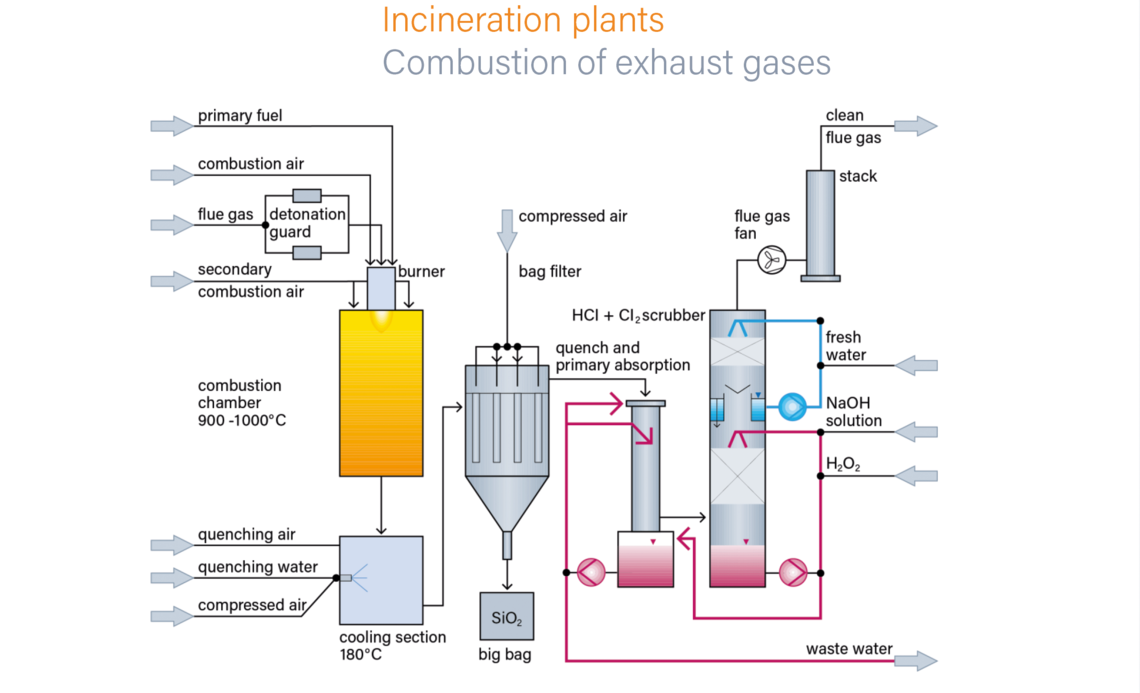

During the production of silanes and silicones as well as in the solar and semiconductor industry, silicon - and partly chlorine-containing exhaust gases are produced. Often incineration is the only way to dispose of these exhaust gases in an environmentally friendly manner.

As a special competence, RVT has been offering complete solutions in the field of silane combustion for over 10 years.

Silicon (e.g. from chlorosilanes) is converted in the flame into extremely light white silicon dioxide (SiO2) fine dust and the chlorine into HCl and Cl2 according to the Deacon equilibrium. Since the SiO2 fine dust tends to stick and sinter when the temperature is too high, a narrow temperature window must be maintained in the combustion chamber.

By arranging the combustion chamber as vertical as possible with subsequent air or water quenching, large deposits of SiO2 dust are avoided. After the fine dust has been separated in a filter system, an HCl / CL2 cleaning stage may follow.

事实上,每个系统都是根据各自的需求进行单独调整的,而不是另一个系统的投资。除了不同的清洗阶段,我们还集成了蒸汽锅炉的废热利用或燃烧空气的预热。此外,所谓的DeNO装置属于我们的投资组合,其中氨用于减少有害氮氧化物(NOX)。