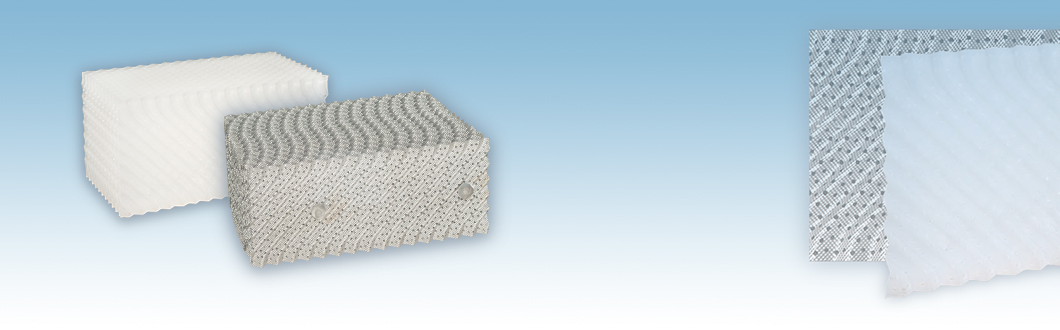

High Performance Packings

The flow channels of high performance packings types RMP S (metal), and RPP S (plastic) are shaped as an S-line.

They are vertically oriented at the bottom and the top of each packing element. This leads to a smooth change of the flow direction at the transition area from one the next packing layer. Furthermore the gas velocity is reduced. Both features reduce the pressure drop and extend the operating range.

This effect has even been further enhanced with the latest generation of high performance packings, the RMP SP and RPP SP. With a constant separation performance, a significant increase in capacity of 15-20% and a significant reduction in pressure loss of up to 50% to the RMP S and RPP S were achieved.

High Performance Packing RMP S

| Type Size | Weight lb/ft3 | Surface ft2/ft3 | Void fraction % |

|---|---|---|---|

| 125 | 4.7 | 38.1 | 99.0 |

| 250 | 6.2 | 76.2 | 98.9 |

| 350 | 8.7 | 106.6 | 98.2 |

High Performance Packing RMP SP

| Type Size | Weight lb/ft3 | Surface ft2/ft3 | Void fraction % |

|---|---|---|---|

| 250 | 6.6 | 76.2 | 98.9 |

Available materials:

Carbon steel, stainless steel, Hastelloy, titanium, and others on request

High Performance Packing RPP S

| Type Size | Weight lb/ft3 | Surface ft2/ft3 | Void fraction % |

|---|---|---|---|

| 250 | 5.9 | 76.2 | 90.0 |

High Performance Packing RPP SP

| Type Size | Weight lb/ft3 | Surface ft2/ft3 | Void fraction % |

|---|---|---|---|

| 250 | 5.9 | 76.2 | 90.0 |

Available materials:

PP, PE, PVDF and others on request