Movable Valve Trays

Movable valve trays are currently the most commonly used type of tray. It is characterized by high capacity and separation efficiency, which is realized over a large variety of mass transfer applications.

Valve with non-moving cage with moving valve disk and sharp-edged orifices in tray plates.

- low-wear

- multi-purpose suitability, also in processes with fouling tendency

A variation of the A3 caged valve providing lower pressure drop by venturi-shaped orifice in the tray deck.

The A11 valve is a variation of the caged valve with reduced orifice diameter. At lower vapor loads, more valves can be fed on the active area of the tray.

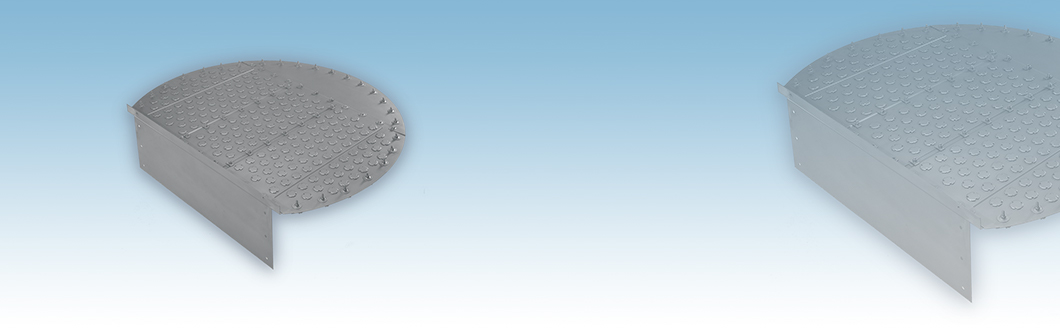

Movable standard valve with integrated legs and sharp-edged orifices in tray plates.

- initial rise is defined by three integrated spacers

- can be equipped with anti-rotation device

- valve rise adjusts to gas flow rates

- suitable for most applications

Same basic valve design as the V1 valve. However a venturi-shaped orifice in the tray deck is used to reduce pressure drop.

The range of V1 and V4 valves is completed by valves without initial rise ( V1X / V4X) and their heavier models ( V1XS / V4XS ).

In order to prevent the liquid flowing through under insufficient steam load, hinged lids are attached to the holes. These lids are pushed upwards at sufficient steam load in the column by the pressure of the steam and the steam can flow through the holes and the liquid. The pressure of the steam then prevents the liquid from flowing through the holes. If the steam load decreases, then the hinged lids close and thus prevent a drainage of the liquid.